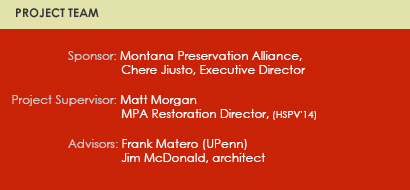

Through a partnership with Montana Preservation

Alliance and the Archie Bray Foundation, interns will engage in the

recording and conservation of historic brick kilns. Skills

learned/applied: documentation and recording, traditional brick masonry

techniques, specialized conservation techniques

For summer

2015, two interns will return to the former site of the Western Clay

Manufacturing Company outside Helena, Montana, an industrial landscape

as important for its historical value as it is for its successful

adaptive reuse as a modern ceramic arts center. This complex site

possesses a broad range of technical and interpretive problems related

to the plant’s original construction and deterioration and current

(non) use. Western Clay Manufacturing Co. was one of the largest brick

and tile plants in Montana during the late 19th to mid-‐20th century.

Partially converted to the Archie Bray Foundation for the Ceramic Arts

in the 1950s, the former brick and tile plant has been closed for many

years and still retains its buildings and much of its machinery, molds

and tools. Plans are currently underway to stabilize, interpret, and

reuse these structures for the Bray’s world famous ceramic arts studio

and other proposed functions such as a museum of industrial clay

products.

The planned project for this year includes the

continued conservation of the site’s iconic brick downdraft or

“beehive” kilns, and surrounding shed complex. Interns will have the

opportunity to apply knowledge and techniques through hands-‐on

training with MPA staff. The work will include architectural recording, masonry stabilization,

repointing, installation of steel brackets and cabling system for seismic

stabilization of kilns, as well as many other tasks. This internship

is meant to reinforce topics already learned in the first year of study

by recording the architecture and its conditions, diagnosing material

and structural problems, designing and executing conservation

treatments.

|

|