|

| Stump

P47 was examined for locations where the epoxy

consolidation method

could be tested. Visual inspection and probing revealed

twenty

candidate locations that were either fully detached (but

with a clear

provenance), or where detachment was incipient. The

guiding principle

for selection was the ultimate vulnerability to

detachment and loss of

interpretive context of the stump for park visitors.

This cohort

represented a variety of characteristics, ranging in

size, shape, mass,

complexity, and levels of deterioration. |

|

|

| Stump

P47, target location for August 2019 in-situ

consolidation testing. View looking south

west. |

|

Over the

course of three days, a set of 6 target locations were

prepped and cleaned, epoxy spot welded

with Araldite 2015, and left to cure while restrained in

situ.

Target location No. 14 was chosen as the best candidate to

test the

consolidation methodology. Both mating surfaces were then

cleaned of

debris with brushes and compressed air. Once the surfaces

were fully

exposed, a small pick was used to pry off any patches of

material that

had begun to delaminate, threatening to compromise the

bonding surface

of the epoxy and wood. Once this was complete, fine steel

wire brushes

were used to further clean and slightly etch the bonding

surfaces (to

enhance adhesion). After a final dust-off with compressed

air, a 1:1

blend of denatured alcohol and acetone was repeatedly

applied to both

surfaces and wiped with a clean, non-pilling, cloth rag to

remove any

oils or residues. |

|

|

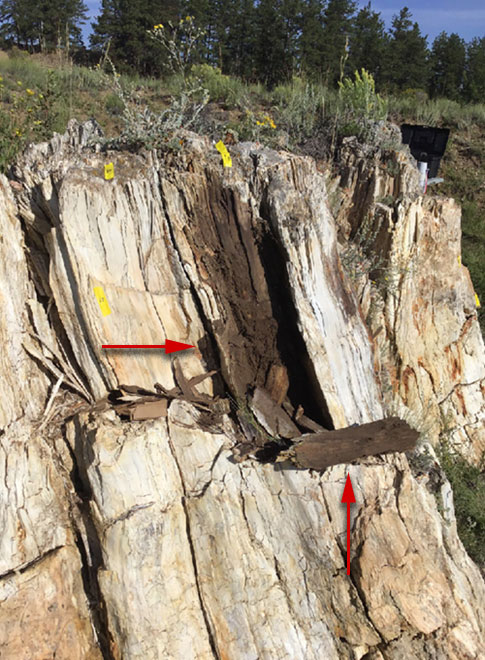

| In

order

to carry out consolidation, a portion of the

stump is removed at

an area of incipient detachment, revealing a

mass of debris and

exfoliating layers (red arrows). |

|

|

| Araldite

2015

epoxy was then applied onto the detached piece in

approximately 10mm

wide ‘spots’. This diameter was predetermined by the

manufacturer’s specifications for the minimum surface

area to achieve

the shear strength required. The height of each

individual ‘spot’ was

adjusted to the necessary distance each application

would have to span.

As a rule of thumb, 1/8” gaps were maintained between

both surfaces for

access to any future removal campaign, Thus, 1/4” high

spots were

created to allow for compression. Once situated in its

final

orientation, 1/8” cardboard shims were placed as

necessary to maintain

this desired gap and to prevent rocking. Finally,

pressure was applied

to the piece and it was secured with adhesive tape. |

|

|

|

|

To better understand the possible

effects of weathering on

the epoxy adhesion tests, seven loose test assemblies

were constructed and

placed at grade around P47. The assemblies are comprised

of previously detached

fragments of petrified wood that had long since lost

their provenance and hold

no contributing significance to the stump’s visual

cohesion.

These ex-situ pieces were then placed

in various

micro-environments in regard to solar exposure,

temperature variations in

proximity to the ground, and areas where snow

accumulation can be expected.

They will be collected after a full season of weathering

and taken back to the

CAC for performance evaluation of the reattachment

technique.

|

|

|

| Fragment 14, located on

P47, after reattachment. Red stucco tape is used

to stabilize the piece during curing. |

|

|

|

The field testing of FLFO petrified

wood consolidation via

epoxy spot welds was successfully implemented. The full

success of this

technique will depend on laboratory testing following a

year of environmental

exposure. Overall, the pilot test was carried out with

the lowest possible

amount of risk to the existing material fabric of stump

P47. All of the epoxy

spot welds were applied to ensure reversibility with no

or minimal/superficial

damage to the existing stump or the fragments used

(based on previous lab

testing of reversibility methods). Additional ex-situ

scatter assemblies were

also tested to provide a greater understanding of the in

situ material

performances of Araldite 2015 epoxy, FLFO petrified

wood, and their bonding

under a variety of environmental conditions.

|

|

| The

inner

surface of fragment piece 14 located on P47,

with epoxy applied.

Note the saize of the sample relative to the

conservator's leg on which

it sits. |

|

This

program was hierarchically prioritised in terms

of predicted treatment beneficial impact and

expense. The most pressing

solution is the elimination of environmental

stress.

FLFO stumps are the primary reason for tourist

visitation and thus

enable monument survival. Stump mothballing

being impractical, and

contrary to site values of display, the best

option is an enclosed or

semi-enclosed shelter followed by well-designed

environmental controls. |

|

|

|