|

An

evaluation of the mechanical properties of

Florissant wood was critical

for understanding the mechanical behaviors of a

variety of treatments.

Testing was conducted at the University of

Pennsylvania’s Laboratory

for the Research of the Structure of Matter

(LRSM).

|

The

site

survey and material characterisation informed a

greater

understanding of stump deterioration mechanisms

and should guide future

research endeavours at Florissant such as

environmental monitoring,

simulation modelling, and the evaluation of

other potential

conservation treatments.

|

| Comparison of American

Building Stone Types with FLFO |

Bulk Density (g)

|

Thermal

Coefficient(X

10-6

m/m⋅ °C)

|

Modulus of Rupture (lbs) |

Compressive Strength

(lbs) |

FLFO

Silicified

Wood

|

2.242

|

6.9-8.5°F (12.52-15.33°C)

|

Range 1562.36- 6549.58

Standard Deviation 1,515.83

|

Radial

~522.91

Tangential ~4220.19

Transverse ~15196.13

|

Indiana

Limestone

114

|

2.17-

2.49

|

2.4-3

|

Range 540-2,220

|

2,720-17,770

|

Ohio

Sandstone

115

|

2.11-

2.15

|

(13-15°C)

|

Range 772-1,177

|

11,679 (avg)

|

Slate

(343 Sample

Average)

|

2.771

|

---

|

11,700

|

---

|

Vermont

Marble

(Shelburne)116

|

2.71

|

---

|

Range 1,481-1,524

|

16,156-22,845

|

Rock of Ages Igneous117

|

---

|

---

|

Range 1,906-3,500

|

23,645-43,524

|

|

Samples

for testing were prepared both for mechanical

strength testing and

thermal coefficient of expansion, to be

described in the following

section, by a combination of continuous-rim

diamond bladed

brick/stone/CMU table-saw, segmented diamond

bladed tile saw, low-speed

diamond wheel saw, and petrographic grinding,

and polishing wheels.

|

|

|

| A preliminary

compression

test was executed to gauge in what ways

its

mechanical properties might be

anisotropic, this was followed by a

three point bending test in order to

understand the modulus of rupture

in one specific grain direction of

interest, tangential, for

through-face or blind pinning. |

|

|

|

|

|

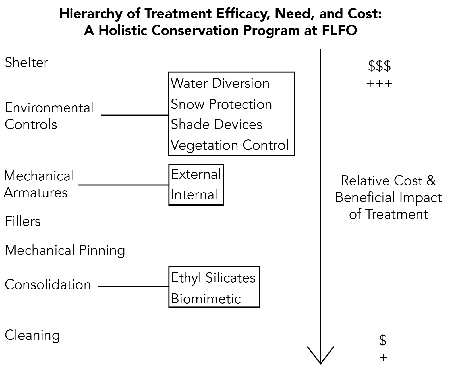

To

date, a conservation treatment of mechanical

pinning was considered as

one measure, among many, in a holistic

conservation program. More

treatment tests will follow.

A program was prioritised in terms of predicted

treatment beneficial impact and expense. The most

pressing solution is

the elimination of environmental stress. FLFO

stumps are the primary

reason for tourist visitation and thus enable

monument survival. Stump

mothballing being impractical, and contrary to

site values of display,

the best option is an enclosed or semi-enclosed

shelter followed by

well-designed environmental controls.

Nevertheless, existing cumulative

damage needs to be stabilized.

|

Assemblies

were

considered unsuccessful if they did not resist

human pull out

strengths. Holes were drilled into an Indiana

limestone proxy with a

cordless Makita Hammer Drill (XPH07) and then

cleaned with a bottle

brush and compressed air. Pins were threaded into

sleeves using a

cordless Makita Driver Drill (XDT14). Pliers were

used by hand to

extract failed assemblies. Those unable to be

extracted went on to a

mechanical pull-out stage at the Laboratory for

Research on the

Structure of Matter (LRSM) at UPenn. Observations

and photographs

recorded modifying assembly variables such as

diameter, dimension and durometer.

Initial pull out failures suggested that

cancellous screws and

woodscrews are too aggressively threaded,

compromising tube integrity.

Nylon threaded rods at small diameters fail

torsionally due to a

combination of drill torque and frictional tube

resistance around 1”

embedment.

|

|

|

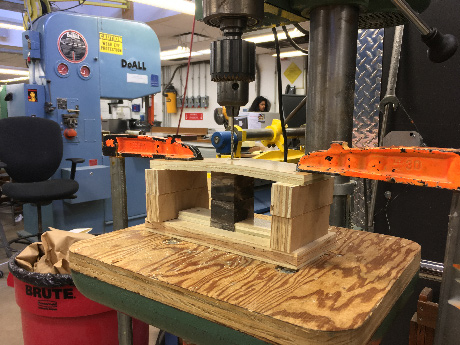

| A jig constructed to

help in the drilling process ensure clean

straight holes for inserting pins for

testing. |

|

General

masonry

tungsten-carbide tipped drill bits were the most

efficient.

During drilling of dark coloured sections black

effluent was discharged

from the samples and were sometimes accompanied by

an oily slick, and

swamp-like smell. Drilling duration was

approximately 20 minutes per

sample because the drill bit was removed every 10

seconds and the hole

flushed with water to cool the sample and drill

bit. Sample compression

during drilling effectively avoided large conical

failure mode

typically associated with through-stone drill

puncturing.

It was decided to test cohort 10 because the pin

failed at 2/3’s the

flexural strength of FLFO wood. C9 was eliminated

as a choice because

it was too close to FLFO modulus of rupture,

leaving little margin for

error.

|

|

|