|

A treatment testing program was developed to identify and select the most appropriate

formulations for reattaching the ceiling.

Morgan Phillip’s seminal article on the use of

acrylic emulsions for flexible and non-flexible reattachment of plaster

to its substrate (1980) was critical to the success of this project.

His mixes

used variations of the same

basic six ingredients including two acrylic emulsions as binders: Rhoplex MC-76 and Rhoplex LC-76.

Rhoplex

MC-76 is the stronger emulsion originally designed as a masonry bonding

agent

while Rhoplex 1950, the accepted replacement for LC-76, is the more

flexible

component originally designed as a binder for elastomeric sealants. In

the case

of all the flexible formulas, the mixtures were based on 3 parts

Rhoplex MC-76

to 1 part Rhoplex 1950 while the non-flexible used only Rhoplex MC-76.

Additionally

a thickener Acrysol ASE-60 was used to control viscosity and flow.

The

unfilled formulations using only the emulsions and thickener were intended for very small gapping.

Filled formulations were also designed to provide for more

significant gaps. For the filled formulations a mix of equal parts

lime, glass microspheres, and fluid petroleum coke were independently

incorporated together.

For these filled formulations where the Acrysol thickener was included,

all

mixtures were first thickened with 20% by volume of the emulsion

formulation prior to

the addition of the premixed dry filler

ingredients.

|

|

| All

testing was carried out at the Mechanical Testing Center of the University of

Pennsylvania under the guidance of the facility director Dr. Alex Radin. Tests

were run on the Instron testing machine model 4206, an electro-mechanical

system which uses a special digital data acquisition system called “Measure”

developed by National Instruments. The data collection system was a Microsoft

Excel add-in allowing for the collection of 2 independent channels of data to

be recorded in a spreadsheet. Channel 1 recorded the displacement of the

machine while channel 2 recorded the applied load. The software recorded 10

scans per second allowing for easy extrapolation for time in minutes. The test

carried out on the samples was a standard tensile strength test which involved

increasing the load applied to the sample by increasing displacement. All

samples were run at the same speed of 0.03 inches per minute until the sample

either failed completely in the case of the rigid samples or peak load had been

surpassed in the case of the flexible samples. |

|

|

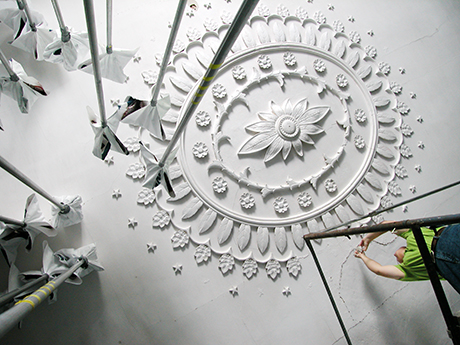

The principle phase of treatment involved injection of the acrylic emulsion adhesive to

reattach areas of the ceiling which had been identified as detached but

which were still in place. Once areas had been identified for injection, holes

were drilled at an interval of approximately ½ inch using a 3/32-inch drill

bit. For each crack drilling was begun in the center of designated lengths

instead of at the ends. The purpose for this was to ensure that only damaged

areas were being drilled. As each consecutive hole was drilled in a given

direction along a crack, the amount of space within the gap between the plaster

and the lathing was monitored using a simple technique of intuitive sensing, when drilling through the plaster resistance

was noted. Once the bit exited the top side of the plaster and entered the

void, it would travel with no resistance until it came in contact with the

lathing and previous plaster repair above. As the drilling progressed along the length

of the crack' the distance the drill would travel unhindered in this gap would

change, reflecting the size of the void between the finished plaster surface

and the lathing. This gapping would continue to shrink until it would disappear

completely. At the point where this gapping ended, the drilling was

stopped and then reinitiated from the first

hole drilled traveling in the opposite direction along the crack.

|

|

|

|

|

| All formulations were first tested for bonding

strength and flexibility in order to identify the best adhesive for the reattachment. |

|

|

| High speed mixing ensured good dispersion of the formulation. |

|

|

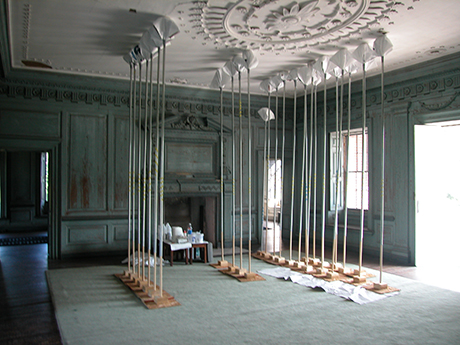

| Using veterinary syringes, the acrylic emulsion was injected into small holes drilled along the pathway of

the cracks. After the emulsion was injected onto the voids, light

pressure was applied to the ceiling surface using custom designed padded extension

poles. |

|  |

| At

the end of each day, treated sections of the ceiling which had

been treated, were left with light pressure over night. |

|

|

|